Model: KCN-12540

4+1 Axis CNC Control(X,Y1,Y2,R,W)

X: Backgauge front and back; Y1,Y2, : Left and right oil cylinder stroke

R : Backgauge up and down; W: Worktable crowning

Main functions and features

1.Overall welded and processed structure.

2.Electric hydraulic proportional servo synchronization, ensuring repeated accuracy.

3. Within one stroke, bending pressure can be controlled at random point, repeatability precision±0.01, parallelism 0.02.

4. Lower worktable has crowning device to anti deflection & upper tool has wedge compensation device.

5.Delem DA52S CNC control system, grating ruler, Rexroth hydraulics, servo motors and other accessories of famous brand are installed for perfect machine performance.

6.Ram stroke(Y1, Y2),backgauge (X, R) are controlled by CNC controller while ball screw and linear guide rail installed for high repeatability precision.

7.Imported ball screw and linear guide are used for rear stopper, to ensure the positioning precision of rear stopper, for processing precision of machine to be higher.

Technical Parameters

| NO. | Item | Parameter | Unit | |

| 1 | Nominal pressure | 1250 | KN | |

| 2 | Table length | 4000 | mm | |

| 3 | Max.Slider stroke | 200 | mm | |

| 4 | Max.Shut height | 460 | mm | |

| 5 | Between columns | 3200 | mm | |

| 6 | Throat depth | 400 | mm | |

| 7 | Main motor power | 7.5 | KW | |

| 8 | Down Speed | 180 | mm/s | |

| 9 | Pressing Speed | 12 | mm/s | |

| 10 | Return Speed | 160 | mm/s | |

| 11 | Control axis | X+Y1+Y2+R +W | / | |

| 12 | X axis Stroke | 500 | mm | |

| 13 | X axis Speed | 300 | mm/s | |

| 14 | R axis Stroke | 150 | mm | |

| 15 | R axis Speed | 50 | mm/s | |

| 16 | Backgauge Stoppers | 2 | / | |

| L | 4500 | mm | ||

| 17 | Overall dimension | W | 1800 | mm |

| H | 2630 | mm | ||

| 18 | Machine weight | 9800 | kg | |

Detailed Pictures

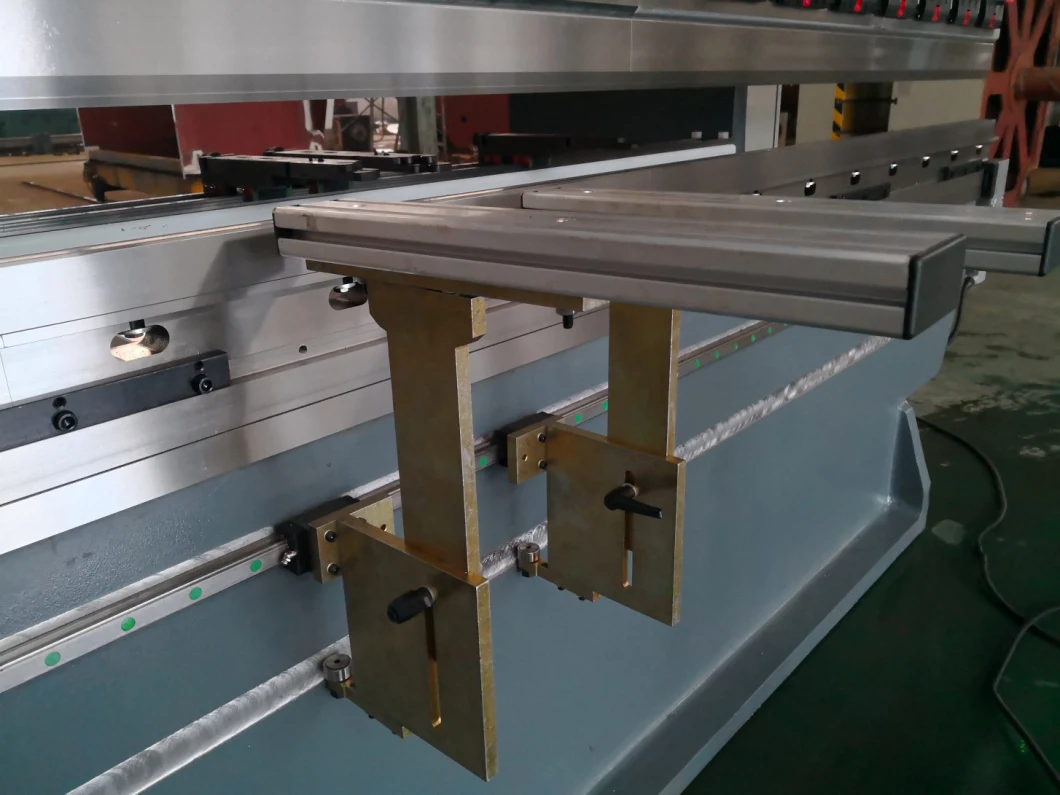

Backgauge with ball screw and linear guide,high precision, fast speed and low noise.

Double sliding front support arm

Double sliding front support arm

installed on the linear guide, High precision CNC table crowning .

movable easy

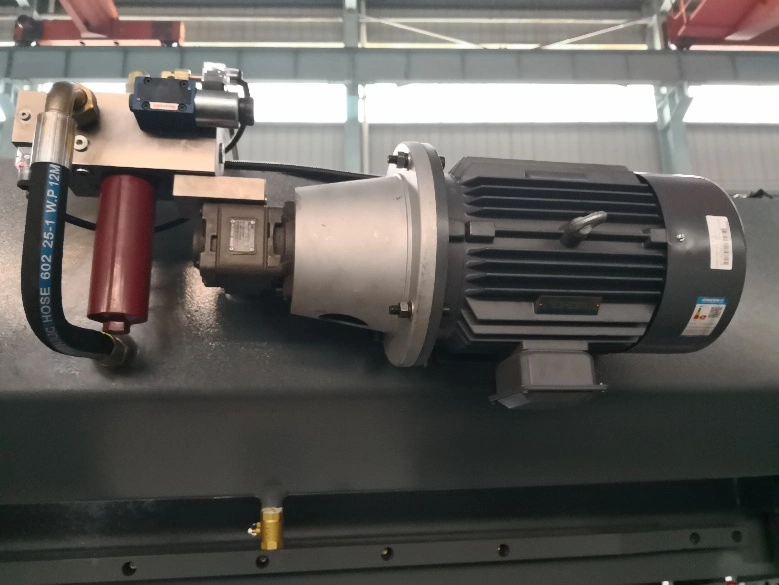

Siemens main motor German brand.

Sunny pump USA brand. European style quick release clamping.

Rexroth valve German brand.

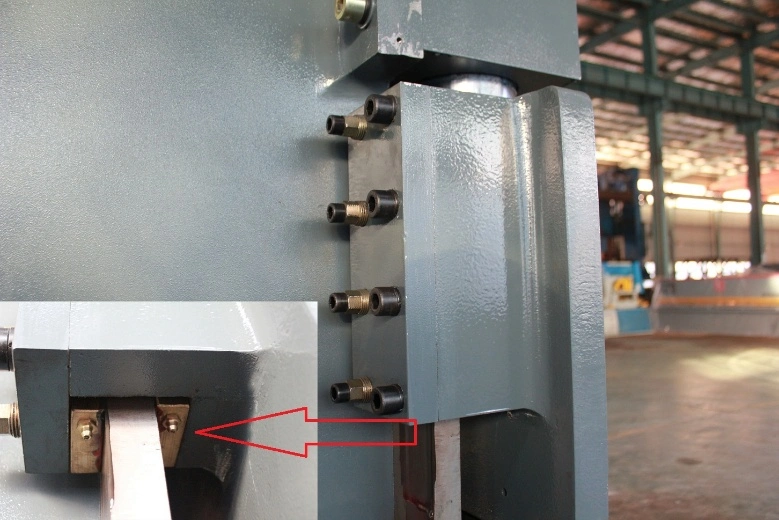

The guideway use the brass, wear-resisting, Pedal switch with emergency stop, safe

long service life. operation, the base with rollers easy to move.

The stopper move left and right on two linear guides.

Main configuration

| Name | Producer |

CNC controller | DA52SDelem Holland brand |

Main motor | Siemens Germany brand |

Electrical components | Schneider France brand |

Gear pump | Sunny USA brand |

Seal ring | NOK Japan brand |

Hydraulic system | Boschrexroth Germany brand |

Ball screw ,Linear guide | HIWIN Taiwan brand |

Grating ruler | GIVI Italy brand |

Tubing connector | EMB Germany Brand |

Servo Motor and drive | Thinkvo China brand |

DA52S CNC controlle

The compact DA-52s is a complete CNC solution for conventional as well as synchronised press brakes.

The panel based control, capable of controlling up to 4 axes, can be integrated in cabinets as well as in an optional pendulant arm housing.

Equipped with the Delem user-friendly user interface, the DA-52s provides all main press brake functionality.

The unique 'hotkey' navigation gives direct access to the programs in memory and enables quick and easy programming of a product. All common bend parameters are located on one page. For advanced parameters an additional page can be selected.

Angle programming of the Y-axis, crowning function and pressure control are standard on board.

USB interfacing enables the use of memory sticks as a fast product and tool backup medium.

DA-52s features:

1. Quick, one page programming

2. Hotkey navigation

3. 7" VGA colour TFT

4. Up to 4 axes (Y1, Y2, and 2 auxiliary axes)

5. Crowning control

6. Tool/material/product library

7. USB, peripheral interfacing

8. Advanced Y-axis control algorithms for closed loop as well as open loop valves

The standard accessories are in the below:

1. Anchor bolt

2. Hex nut

3. Seal ring

4. Gasket

5. Grease gun

6. Allen wrench

7. Foot switch

8. Front support arms

9. Electrical box key, control panel key

10. Operation manuals

Our Factory-NANJING Jinqiu CNC Machine Tool Co., Ltd

has been focusing on research and design, manufacturing and sales of better prices with better quality machines such as Press Brakes, Shearing Machines,Rolling Machines,Press Machine,Ironworkers,Pipe Bend Machine, press brake tooling blade and so on, our brand is Kingball ,since it was established in 2003. Kingball is a true expert of machine- manufacturing based on more than 10 years experience.

Our Company has got the certification of ISO9001 SGS CE TUV and BV have been exported to more than 60 countries including UK, USA, Italy, Spain, Ireland, India, Thailand, Malaysia, South Africa, and so on.

We have 28,000 square meters workshop, advanced production equipment,220 experienced staff, and strictly effective quality assurance system. Kingball selects best material and parts for the machines and the most important is Kingball manufactures most of the parts by itself for better to control the quality. Therefore Kingball brand products win the reputation of practical, reliable and durable.

Nowadays our company is developing the global market, We are currently looking for all agents and powerful cooperation globally to sell our products worldwide. We are glad to try our best to supply Free technical support and related information all of the China Machine. Any advise you have , please do not hesitate to contact with us for your requirement, thank you!

Our customers from all over the world!

Certificates

Any questions,feel free to contact me,thank you!

Company Name | Nanjing Jinqiu CNC Machine Tool Co.,Ltd |

Address | Shiqiu Industrial Park,Nanjing,Jiangsu,China |

Website | jinqiumt.en.made-in-china.com |

Phone | +8615380952014 |

| linda@jinqiu.cc |