Product Description

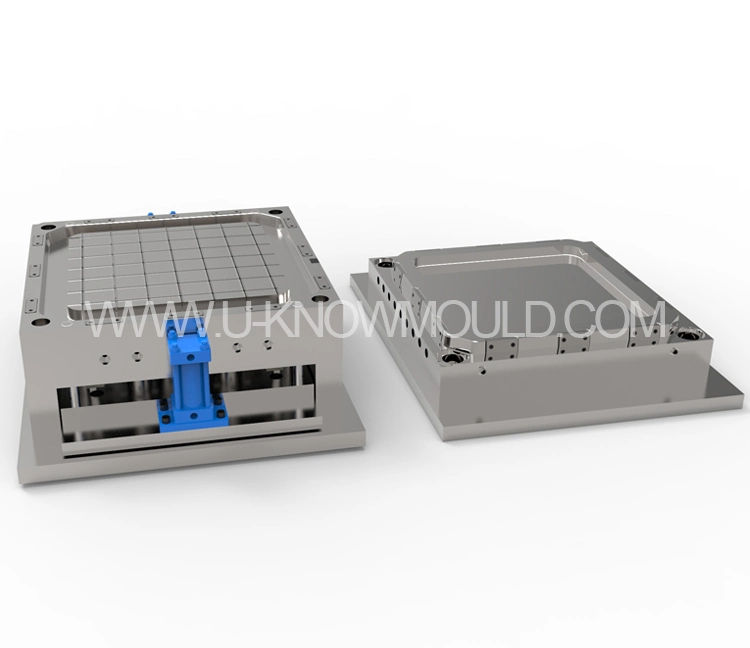

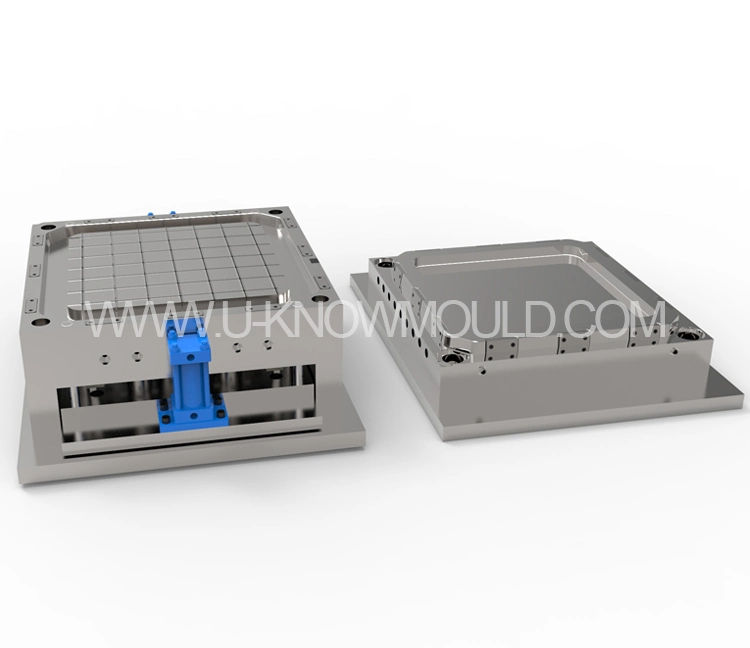

We use advanced technology and quality materials to offer you the high-grade product for plastic tea table mould. We also use 718 easy-cut pre-hard quality plastic mold steel production to ensure excellent hardness, wear resistance, strength and core toughness, which greatly increases the mould life.To avoid the surface deformation of the plastic table, we use CNC precision engraving, CNC lathe, EDM, wire cutting and other mold finishing equipment which can satisfy all your requirement about the smoothness of the plastic product.

About Us

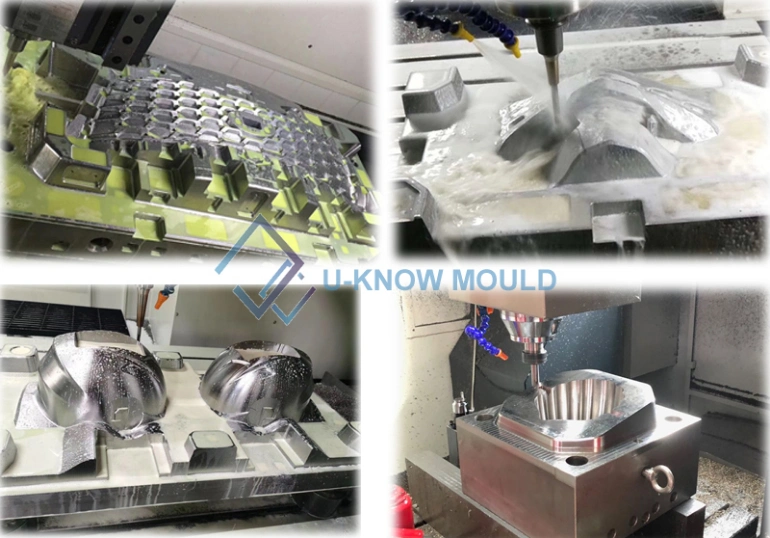

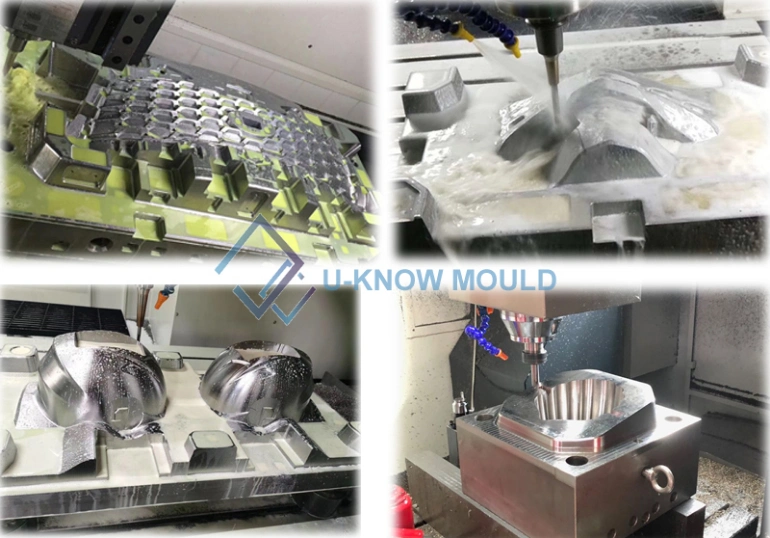

U-KNOW MOULD is located in Huangyan,Zhejiang,China.It is known as one of the best manufacturers and exports for all kinds of plastic mould for commodity items,such as chair mould,crate mould,bucket mould,medcial mould and so on. We are a full rang of CNC machining centers,large gantry milling machines,vertical milling machines,CNC engraving machines,electric spark(EDM),wire-cutters,ect.We have advanced technologies fir CAD/CAM/CAE design and rich experiences in mould making.We have 5 senior designer and 20 engineers who have more than 15 years experiences in mouldmaking. Our designers are good at designing new products and mould structure.We always focus on perfection on quality and services.We would like to supply our best services and our best products to all the customers.

Product Line

1) Clients offer 3D drawings and sufficient information of the mould and plastic housing mold

2) We offer the quote of plastic enclosure mold and injection molding (plastic cover) in half a day

3) Clients consider our quotes

4) Clients place the order

5) We design and manufacture the plastic molds in lead-time after confirming the drawing and detailed information with clients again

6) Plastic mould trial samples sent to clients to get their confirm if there is any modification before mass production

7) Arrange mass production at once and finish the production before the lead-time

8) Delivery by sea or air on time

Packaging & Shipping

Anti-rust oil is painted first, then plastic film, and finally wooden case.

Sent together with the mould:

a) Mould manual instruction

b) Engineering drawing in flash disk

c) One more set of mould spare parts: heater, ejector pin, bush, water nozzle, water pipe, hanging ring.

FAQ

1.

Q:What is your payment term?

A:Mould:50% deposit and 50% balance samples are approved.

Batch Production:50% deposit and 50% balance before shipment.

2.

Q:Whats the quality assurance we provided and how do we control quality ?

A:Established a procedure to check products at all stages of the manufacturing process - raw materials, in process materials, validated or tested materials, finished goods, etc. Besides, we have also developed a procedure which identifies the inspection and test status of all items at all stages of the manufacturing process.

3.

Q: Is it possible to visit your factory?

A:Our company is located in TAIZHOU,ZHEJIANG,CHINA. It is very convenient to visit us, and all clients from all over the world

are highly welcome to us. We warmly look forward to your visiting!

4.

Q:How many mould could you make every month?

A:30-40 sets.

We use advanced technology and quality materials to offer you the high-grade product for plastic tea table mould. We also use 718 easy-cut pre-hard quality plastic mold steel production to ensure excellent hardness, wear resistance, strength and core toughness, which greatly increases the mould life.To avoid the surface deformation of the plastic table, we use CNC precision engraving, CNC lathe, EDM, wire cutting and other mold finishing equipment which can satisfy all your requirement about the smoothness of the plastic product.

About Us

U-KNOW MOULD is located in Huangyan,Zhejiang,China.It is known as one of the best manufacturers and exports for all kinds of plastic mould for commodity items,such as chair mould,crate mould,bucket mould,medcial mould and so on. We are a full rang of CNC machining centers,large gantry milling machines,vertical milling machines,CNC engraving machines,electric spark(EDM),wire-cutters,ect.We have advanced technologies fir CAD/CAM/CAE design and rich experiences in mould making.We have 5 senior designer and 20 engineers who have more than 15 years experiences in mouldmaking. Our designers are good at designing new products and mould structure.We always focus on perfection on quality and services.We would like to supply our best services and our best products to all the customers.

Product Line

1) Clients offer 3D drawings and sufficient information of the mould and plastic housing mold

2) We offer the quote of plastic enclosure mold and injection molding (plastic cover) in half a day

3) Clients consider our quotes

4) Clients place the order

5) We design and manufacture the plastic molds in lead-time after confirming the drawing and detailed information with clients again

6) Plastic mould trial samples sent to clients to get their confirm if there is any modification before mass production

7) Arrange mass production at once and finish the production before the lead-time

8) Delivery by sea or air on time

Packaging & Shipping

Anti-rust oil is painted first, then plastic film, and finally wooden case.

Sent together with the mould:

a) Mould manual instruction

b) Engineering drawing in flash disk

c) One more set of mould spare parts: heater, ejector pin, bush, water nozzle, water pipe, hanging ring.

FAQ

1.

Q:What is your payment term?

A:Mould:50% deposit and 50% balance samples are approved.

Batch Production:50% deposit and 50% balance before shipment.

2.

Q:Whats the quality assurance we provided and how do we control quality ?

A:Established a procedure to check products at all stages of the manufacturing process - raw materials, in process materials, validated or tested materials, finished goods, etc. Besides, we have also developed a procedure which identifies the inspection and test status of all items at all stages of the manufacturing process.

3.

Q: Is it possible to visit your factory?

A:Our company is located in TAIZHOU,ZHEJIANG,CHINA. It is very convenient to visit us, and all clients from all over the world

are highly welcome to us. We warmly look forward to your visiting!

4.

Q:How many mould could you make every month?

A:30-40 sets.